Q1: What types of glass do you mainly use for your medical glass bottles?

We specialize in two pharmacopoeia-compliant medical glasses: neutral borosilicate glass (USP Type I), whose superior chemical stability and thermal-shock resistance make it the first choice for injectables, vaccines and high-end biologics; and surface-treated soda-lime glass (Type III), which offers adequate stability for oral solutions, powders and non-injectable drugs.

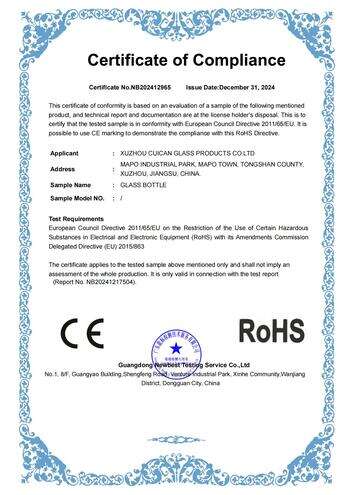

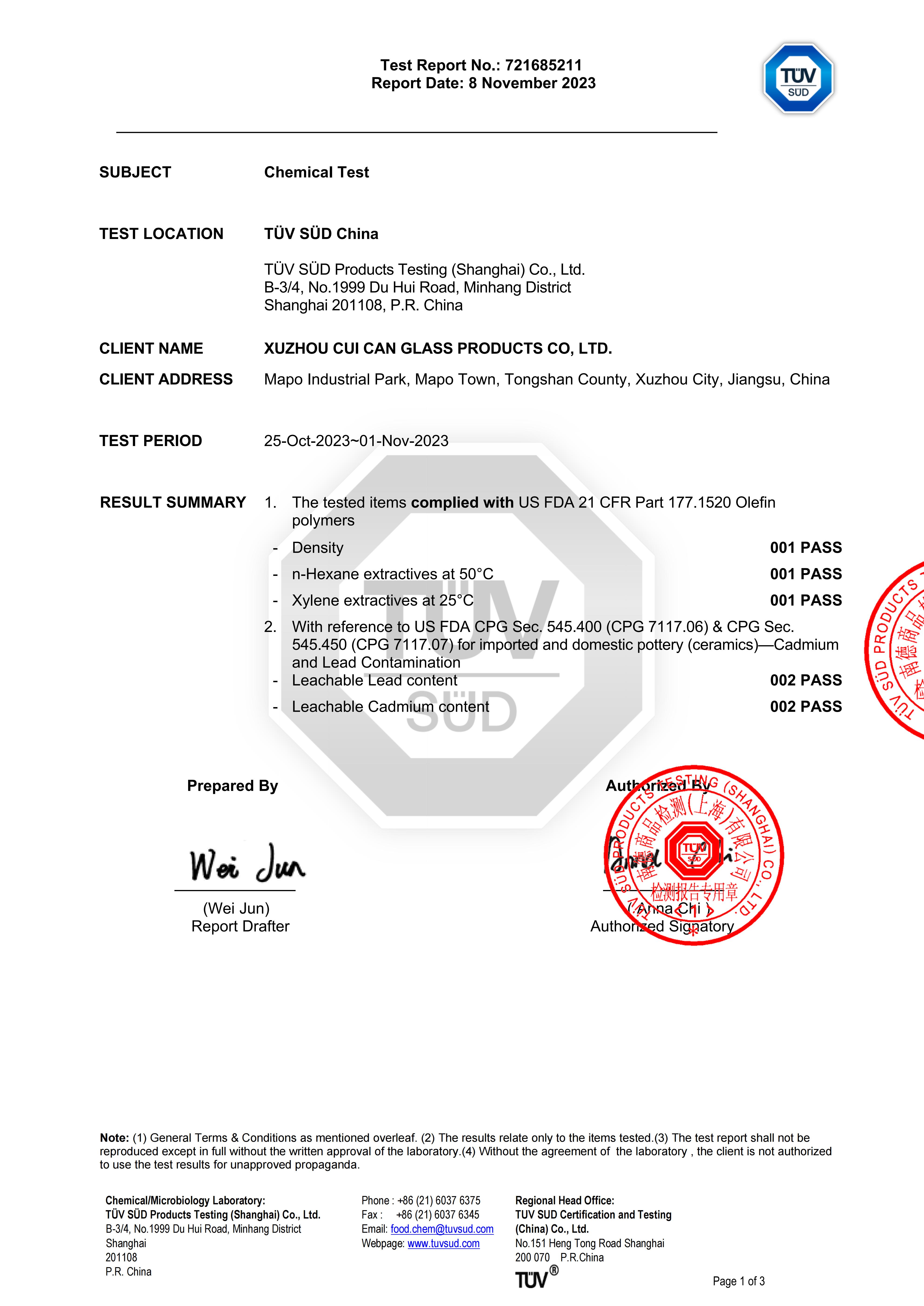

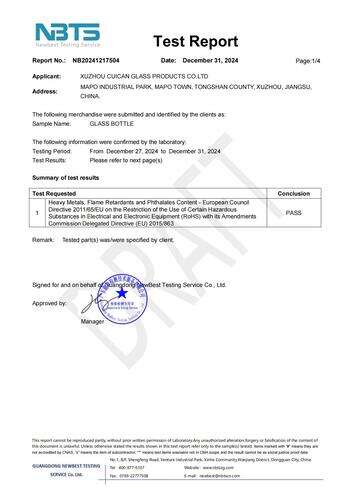

Q2: Which international standards and certifications do these glass bottles comply with?

Our production strictly follows the USP, EP and ChP pharmacopoeia standards, fully complies with the ISO 9001, ISO 15378 quality system and ISO 10993 biosafety requirements, and other relevant certifications can be provided as required.

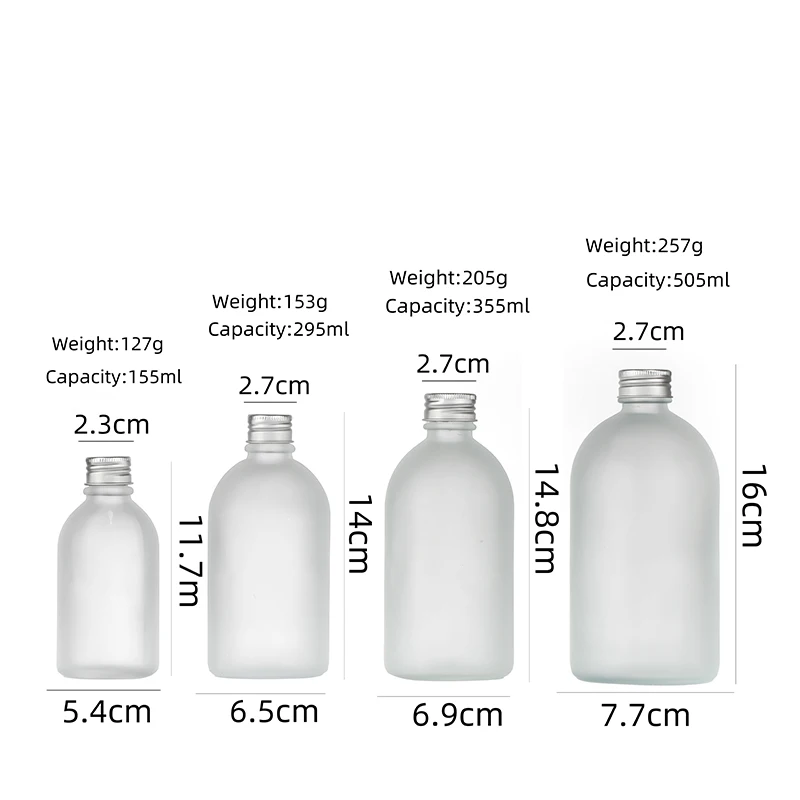

Q3: What capacities of medical glass bottles can you provide?

We can offer a very wide range of capacities, from small 1-milliliter ampoules to large-capacity 1000-milliliter infusion bottles. Common specifications include 2ml, 5ml, 10ml, 20ml, 50ml, 100ml, 250ml, 500ml, etc. We also support customization based on the special needs of our customers.

Q4: What are the options for bottle mouth specifications?

We offer a variety of internationally recognized standard bottle mouth specifications, such as:

13mm, 20mm, 28mm, 32mm, etc. (conforming to ISO standards).

This ensures that our glass bottles can be perfectly matched with the mainstream rubber stoppers, aluminum caps and plastic caps on the market, facilitating customers' filling and capping.

Q5: How is the water resistance of glass bottles?

We attach great importance to the chemical stability of glass. Especially our neutral borosilicate glass bottles , with water resistance reaching USP/EP level 1 , have an extremely low alkali leaching rate, and can effectively protect highly sensitive pharmaceutical contents from chemical reactions.

Q6: Can customized colors, prints and logos be provided?

Of course you can. We offer flexible customization services, including glass color and screen printing. We can print scale lines, brand logos, batch numbers, capacity and other information. The colors are firm and meet the requirements of durability tests. At the same time, we can also mold and customize unique bottle shapes for you.

Q7: Can samples be provided? Is it necessary to pay?

We are glad to provide samples for potential customers for testing and evaluation. For standard products, we usually offer free samples , but customers need to bear the shipping cost. The policy for custom samples will be negotiated separately based on specific circumstances.